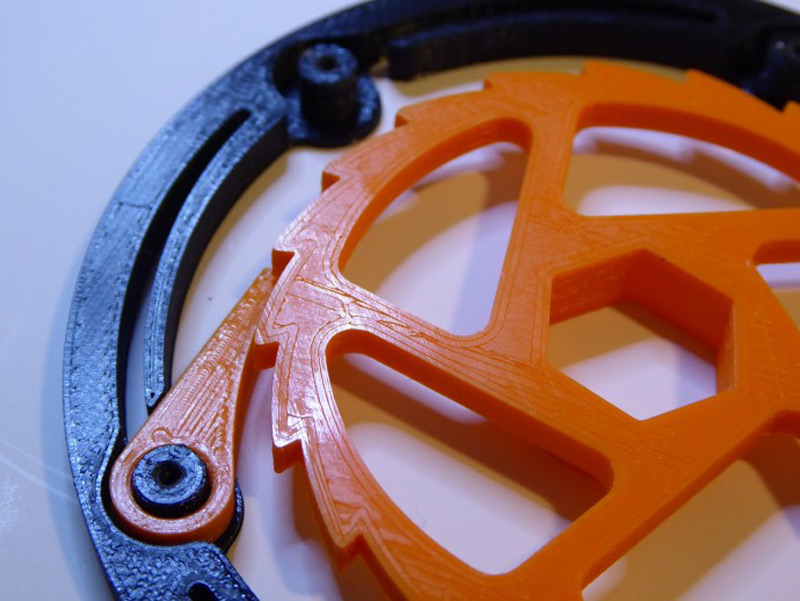

Christoph Laimer, a Swiss engineer, just unveiled world’s first 3D printed tourbillon watch running by itself. Every last part are made from 3D-printed plastic. Even the flexible spring came from a 3D printer, which is why this watch isn’t especially accurate. But since there are 3D printers capable of creating parts from actual metal, there’s no reason this timepieces’s accuracy can’t be greatly improved.

World’s First 3D-Printed Watch With Tourbillon by Laimer Christoph

The only non-printed parts are the metal pins used as the axes for the gears, and some screws and washers (aka “vitamins” as non-printed components are called in the 3D printing community). Perhaps most impressive about Laimer’s work is the the Tourbillon 1000%, which is a 3D printed tourbillon with a co-axial escapement. Tourbillon 1000% isn’t a complete watch though; it’s just the tourbillon mechanism and fourth wheel, and doesn’t include any gear train or barrel.

World’s First 3D-Printed Watch With Tourbillon by Laimer Christoph

It doesn’t run by itself; instead it requires a human to provide power to the tourbillon carriage while holding the fourth wheel. Laimer assesses the tourbillon as “a nice piece of complex mechanics spinning in the watch” adding that “with the concentric design, the minute and hour hands are hovering with invisible hands around the tourbillon.”

The whole thing is 98mm in diameter, and 93mm tall.