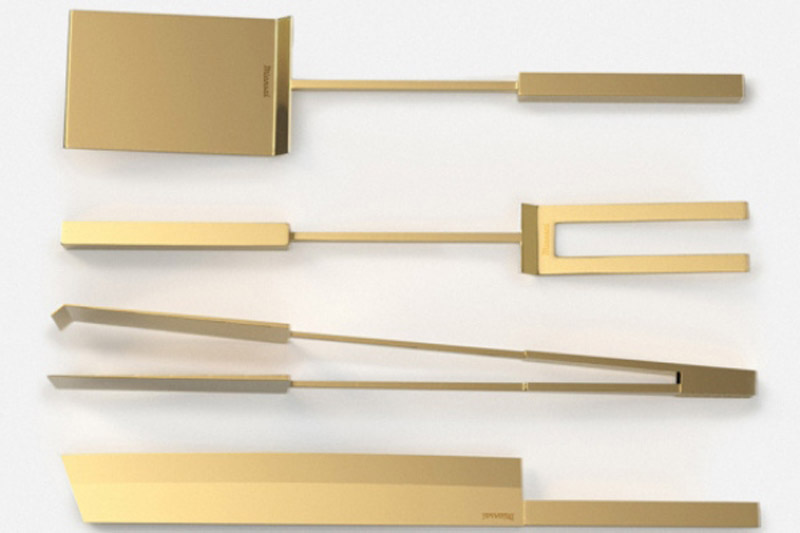

As a student, German designer Oliver Aschenbrenner fell in love with the GB500, but he didn’t have the money to buy it.

He managed to raise some money for the deposit, so he would return with the rest of his money six months later. He pushed the bike home, because it wouldn’t start in the cold winter weather. Over the years the motorcycle has undergone certain changes. First, a Mikuni TM40 carb and SR-Racing exhaust system were installed. SOHC radial four-valve engine is also arranged. Not much, but enough to take Oliver on the road through Italy, France and Spain.

271 Desing Honda GB500

Years slowly took their toll, but Oliver in the meantime became a motorcycle designer, so he decided to dismantle his Honda and to make it in his own way. After a time spent in British company Triumph, Oliver returned to Bavaria, founded a company named 271 Design and arranged his motorcycle.

“Perfect lines, volumes and proportions are important to me as a designer,” says Oliver. “The original tank and frame were the foundation. My early training was in the field of building aircraft, so I also have a strong inclination towards technology. I wanted to build the strongest, most durable Honda RVFC engine too!”

The reservoir is now the focus of this cafe racer, subtly repositioned. It also hides a new electrical system, as well as a Motogadget control unit. Oliver has also stripped the frame to the bare essentials, powder coated it, and shortened the rear end, using CAD for the design. He even took on the mold construction and carbon laminating himself: “Everything had to be minimal, small and of the highest quality,” he says.

The suspension was relatively simple in comparison: Showa forks from a Honda CB450S, shortened slightly and fitted with Wilbers progressive springs, and Ikon shocks at the rear.

271 Desing Honda GB500

Things started to get trickier when it came to the engine. “After months of tedious research and many discussions with RFVC specialists, I knew what I had to change,” says Oliver. “The catch was cost and time.”

“In economic terms, increasing the performance of these motors is complete nonsense. Getting a made-to-measure piston, connecting rod and crankshaft strained my finances. There was also a very long waiting period, and for a while I was afraid to carry on with the project.”

Oliver continued, but to reduce costs, he decided not to change the volume and head of the cylinder, and the transmission remained untouched. Everything else is completely arranged.

Ralf Welzmüller from ABP Racing worked on the cylinder head and he successfully did everything that was needed. The end result was a 100% reliable head of the cylinder, and a calm conscience for Oliver, as he later stated himself.

The heavily revised engine now has 2,000 kilometers on the clock, and thanks to the mods and the hot cam, it’s performing even better than expected.

All in all, this GB500 looks perfect. But as with most designers, Oliver isn’t satisfied and he is thinking of fixing his work, improving the fork and shielding the armor to a minimum.

271 Desing Honda GB500